Attack Microchip Microcontroller IC Chip Source Code

Attack Microchip Microcontroller IC Chip Source Code

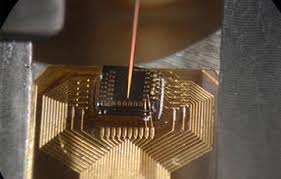

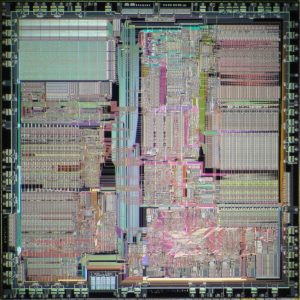

Attack Microchip Microcontroller IC Chip starts from deprocessing the external package of MCU, this is a basic technique for MCU crack and Microprocessor Source Code reading;

Attack Microchip Microcontroller IC Chip starts from deprocessing the external package of MCU, this is a basic technique for MCU crack and Microprocessor Source Code reading

Three basic deprocessing methods are used: wet chemical etching, plasma etching, also known as dry etching, and mechanical polishing. In chemical etching each layer is removed by specific chemicals. Its downside is its isotropic nature, i.e. uniformity in all directions. That produces unwanted undercutting. As a result, narrow metal lines will have a tendency to lift off the surface.

Isotropic etching also leads to etching through holes such as vias, resulting in unwanted etching of underlaying metallization. Plasma etching uses radicals created from gas inside a special chamber. They react with the material on the sample surface to form volatile products which are pumped out of the chamber. As the ions are accelerated in an electric field they usually hit the surface of the sample perpendicularly.

Microcontroller Cracking Without Part Number

Microcontroller Cracking Without Part Number

Microcontroller Cracking Without Part Number

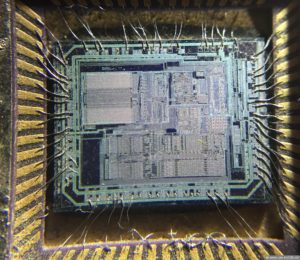

With MCU design and manufacturing technology continues to evolve, Microcontroller cracking method is also emerging, alteration on Microcontroller’s package, erase silkscreen and burn out pins of Microcontroller as well as other methods being applied on electronic devices at home and abroad, erase silkscreen on Microcontroller is the most common method.

For such kind of Microcontroller cracking, must first get to know the exact model number of the Microcontroller, a majority of companies use observation method like assessing the external circuit to estimate the probable models of Microcontroller, due to continuous development of the industry, the limitations of this approach has been growing, mainly in the following several reasons:

1. Because Microcontroller from same company often has compatible pins (for example: MCU from PIC series and MCU of AVR series), so even determine which series of this Microcontroller generously, but still difficult to determine its concrete model;

2. Today, different companies have compatible pins of Microcontroller is also very common (such as EMC78P156 and IC16C54C, etc.), which added more difficult for us to determine the final model number of Microcontroller;

3. Because different companies have different Microcontroller programming port and verified pins distribution, especially the distribution of high-voltage VPP pin is different, so before the Microcontroller model has not been determined, random use of programmer to read the its program (which is currently the most popular approach), it is very likely to cause damage of inside content of flash and eeprom memory.

Break Microcontroller Memory Failure Possibility

Break Microcontroller Memory Failure Possibility

Break Microcontroller Memory Failure Possibility

Refers to Break Microcontroller Memory success rate, both our customers and us are all very concerned about this questions, we all want a quick one-time successful microcontroller memory Break, but because crack MCU is not a very simple process, sometimes we may encountered many unforeseen problems, even the same microcontroller memory, designers may use different encryption methods, requires different means to copy the content inside microcontroller memory.

Here we combine our experience to talk about these possibilities of failure during mcu cracking.

Break Microcontroller Memory do have probability of failure, according to our experience and concerning about the probability, there is about 1% of failure probability when break an microcontroller memory, there is 0.3% probability of damage mother microcontroller memory.

Therefore, we can not either guarantee 100% is successful, or guarantee 100% doesn’t destroy or damage mother microcontroller memory, please carefully take this risk into consideration.

But we conduct a careful summary about the failure of IC clone (those parts involve our core technologies are not listed), and engage in a series of measures to reduce this probability to greatest level, the current probability of failure has become lower and lower, furthermore we promise not charge customers any fees if break microcontroller memory content fail.

Attack Microchip IC MCU Encrypted Code

Attack Microchip IC MCU Encrypted Code

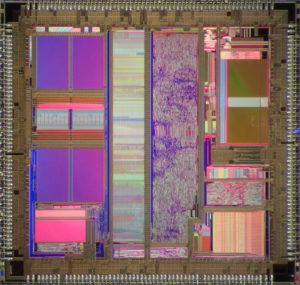

Attack Microchip IC MCU and extract encrypted code from microcontroller’s memory, program of flash memory and data of eeprom memory will be integrated as a united file called firmware;

Attack Microchip IC MCU and extract encrypted code from microcontroller’s memory, program of flash memory and data of eeprom memory will be integrated as a united file called firmware

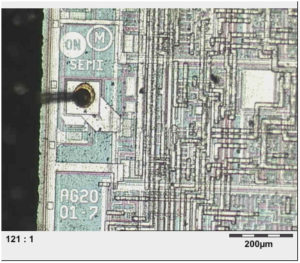

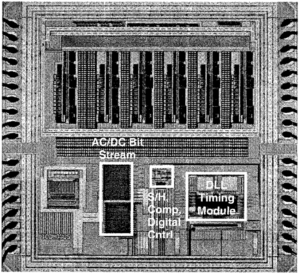

There are two main applications of deprocessing. One is to remove the passivation layer, exposing the top metal layer for microprobing attacks. Another is to gain access to the deep layers and observe the internal structure of the chip.

Recover Microchip PIC18F2423 memory program

Recover Microchip PIC18F2423 memory program

Recover Microchip PIC18F2423 Memory Program

Recover Microchip PIC18F2423 memory program includes recover the content from both eeprom and flash, so it is necessary to get a better knowledge of the internal structure:

12-bit,up to 13-channel Analog-to-Digital

Converter module (A/D):

– Auto-acquisition capability

– Conversion available during Sleep

Dualanalog comparators with input multiplexing

High-currentsink/source 25 mA/25 mA

Threeprogrammable external interrupts

Fourinput change interrupts of IC recoverion

Upto 2 Capture/Compare/PWM (CCP) modules, one with Auto-Shutdown (28-pin devices)

EnhancedCapture/Compare/PWM (ECCP) module (40/44-pin devices only):

– One, two or four PWM outputs

– Selectable polarity

– Programmable dead time

– Auto-shutdown and auto-restart

MasterSynchronous Serial Port (MSSP) module supporting 3-wire SPI (all 4 modes) and I2C™

Master and Slave modes

EnhancedUSART module:

– Supports RS-485, RS-232 and LIN 1.2

– RS-232 operation using internal oscillator block (no external crystal required)

– Auto-wake-up on Start bit

– Auto-Baud Detect

Run:CPU on, peripherals on

Idle:CPU off, peripherals on

Sleep:CPU off, peripherals off

Idlemode currents down to 5.8 ìA, typical

Sleepmode current down to 0.1 ìA, typical

Timer1Oscillator: 1.8 ìA, 32 kHz, 2V

WatchdogTimer: 2.1 ìA

FourCrystal modes, up to 25 MHz

4xPhase Lock Loop (available for crystal and Two-SpeedOscillator Start-up internal oscillators)

TwoExternal RC modes, up to 4 MHz

TwoExternal Clock modes, up to 25 MHz

Internaloscillator block:

– 8 user-selectable frequencies, from 31 kHz to 8 MHz

– Provides a complete range of clock speeds from 31 kHz to 32 MHz when used with PLL

– User-tunable to compensate for frequency drift

Secondaryoscillator using Timer1 @ 32 kHz

Fail-SafeClock Monitor:

– Allows for safe shutdown if external clock stops

Attack ATmega MCU Embeded Firmware

Attack ATmega MCU Embeded Firmware

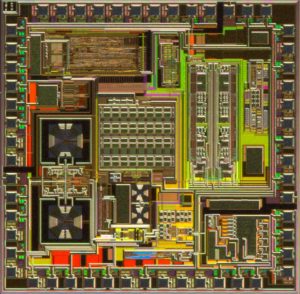

Attack ATmega MCU encryption system by using focus ion beam technique which one of the most commonly used Microcontroller unlocking methods to cut off the security fuse bit and readout Embeded Firmware from microprocessor memory;

Attack ATmega MCU encryption system by using focus ion beam technique which one of the most commonly used Microcontroller unlocking methods to cut off the security fuse bit and readout Embeded Firmware from microprocessor memory

The opposite process to chip fabrication is called deprocessing. A standard CMOS chip has many layers. The deepest doping layers inside the substrate form the transistors. The gate oxide layer isolates the gate from the active area of the transistors. The polysilicon layer on top of it forms the gates and interconnections. The interlayer oxide isolates conducting layers.

Metal layers, usually made of aluminium (Al), form the signal wires, and they are connected with other layers through ‘via’ plugs (Al, W, Ti). Finally, a passivation layer made out of silicon oxide SiO2 or nitride Si3N4 protects the whole structure from moisture and air which could harm the die. In plastic packages the passivation layer is covered with a polymer layer, usually polyimide, to protect against sharp grains in the compound during the package formation.

Microcontroller Break Categories

Microcontroller Break Categories

Microcontroller Break Categories

We can distinguish five major microcontroller break categories:

Microprobing techniques can be used to access the chip surface directly, so we can observe, manipulate, and interfere with the integrated circuit.

Reverse engineering is used to understand the inner structure of semiconductor chip and learn or emulate its functionality. It requires the use of the same technology available to semiconductor manufacturers and gives similar capabilities to the attacker.

Software microcontroller breaks use the normal communication interface of the processor and exploit security vulnerabilities found in the protocols, cryptographic algorithms, or their implementation.

Eavesdropping techniques allows the microcontroller breaker to monitor, with high time resolution, the analog characteristics of supply and interface connections and any electromagnetic radiation by the processor during normal operation.

Fault generation techniques use abnormal environmental conditions to generate malfunctions in the processor that provide additional access.

All microprobing and reverse engineering techniques are invasive microcontroller breaks. They require hours or weeks in specialised laboratory and in the process they destroy the packaging.

The other three are non-invasive microcontroller breaks. The microcontroller breaked device is not physically harmed during these microcontroller breaks.

The last microcontroller break category could also be semi-invasive. It means that the access to the chip’s die is required but the microcontroller break is not penetrative and the fault is generated with intensive light pulse, radiation, local heating or other means.

Attack ATmega MCU Microcontroller Firmware

Attack ATmega MCU Microcontroller Firmware

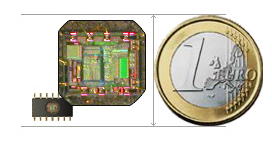

Attack ATmega MCU Microcontroller Firmware from flash memory and eeprom memory, then extract the source code from its memory and copy the firmware to new Microprocessor;

Attack ATmega MCU Microcontroller Firmware from flash memory and eeprom memory, then extract the source code from its memory and copy the firmware to new Microprocessor;

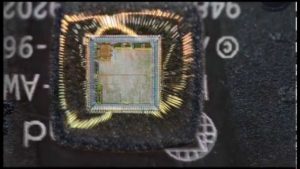

The same partial decapsulation technique can be used for smartcards as well (see below figure) although not all of them would maintain electrical integrity. Very often the chip has to be decapsulated completely and then bonded onto a chip carrier. Other methods used for opening the chip packages are described in the literature and only very few of them require expensive tools.

One interesting approach suggests using an acid resistant tape to prevent the acid reacting with unwanted parts. The chip is placed on a glass to prevent lead bending and then covered with acid resistant tape. The tape over the area to be etched is cut away and the whole package is then immersed in a chemical solution to etch away the plastic. This method is limited to QFP, SOP, BGA and other thin packages.

Attack ATmega IC Chip Microcontroller AVR Program

Attack ATmega IC Chip Microcontroller AVR Program

Attack ATmega IC Chip Microcontroller AVR and readout program and data from flash and eeprom memory, decrypt the firmware in the format of binary or heximal to un-encrypted status;

Attack ATmega IC Chip Microcontroller AVR and readout program and data from flash and eeprom memory, decrypt the firmware in the format of binary or heximal to un-encrypted status;

A very similar approach can be used for decapsulating chips from the rear side. The only obstacle is the copper plate under the chip die which reacts slowly with the fuming nitric acid. That could create problems if the automatic decapsulator is used because the surrounding plastic will be etched away before this copper plate and the chip leads are very likely to be damaged (Figure below).

However, access to the rear side of the die can be established without using chemical etching. The chip package can be milled down to the copper plate which is then removed mechanically. The residues of the glue used to attach the die to the plate can be removed with solvents or by scraping it off with a wooden toothpick stick.

Attack ATmega IC Embeded Firmware

Attack ATmega IC Embeded Firmware

Attack ATmega IC can help engineer to reset the status of ATmega Microcontroller from locked to unlocked one by crack MCU technique, then extract the ic code from program memory;

Attack ATmega IC can help engineer to reset the status of ATmega Microcontroller from locked to unlocked one by crack MCU technique, then extract the ic code from program memory;

For decapping chips in large quantities an automatic decapsulation system can be used, for example PA103 from Nippon Scientific. Very little skill and experience is required to operate it, and packages can be decapped easily even by unskilled workers.

Such systems cost over £10,000 and are bought by relatively large labs only. They also consume ten times more acid compared to the manual method, and their waste has to be disposed of in a proper way to avoid harm to the environment.