Attack DSP Chip Encrypt Code

Attack DSP Chip Encrypt Code

Attack DSP Chip by chemical decapsulation, through which it will be able to get access to the databus of microcontroller memory and extract encrypted code from flash and eeprom memory;

Attack DSP Chip by chemical decapsulation, through which it will be able to get access to the databus of microcontroller memory and extract encrypted code from flash and eeprom memory;

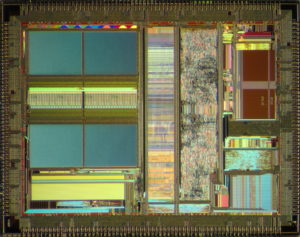

The acid residues can be removed from the etched plastic and from the chip surface by ultrasonic treatment. For that the chip is placed into a beaker with acetone and then put in an ultrasonic bath for 1–3 minutes. After washing the chip with acetone and drying it in an air jet, we have a clean and fully operational chip.

Attack DSP IC Chip Encrypted System

Attack DSP IC Chip Encrypted System

Attack DSP IC Chip program memory to extract encrypted data from MCU memory, disable the tamper resistance system by Microcontroller unlocking;

Attack DSP IC Chip program memory to extract encrypted data from MCU memory, disable the tamper resistance system by Microcontroller unlocking

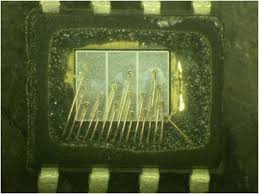

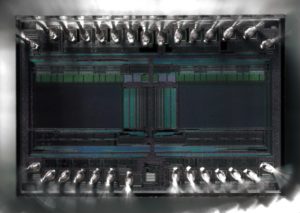

The acid is normally applied in small portions with a pipette into a pre-milled hole in a chip preheated to 50–70˚C (Figure 51). After 10–30 seconds the chip is sprayed with dry acetone from a washing bottle to remove the reaction products. This process has to be repeated several times until the die is sufficiently exposed. To speed up the process, the chip can be placed in a sand bath and the acid can be preheated in a glass beaker. see below picture:

Attack DSP MCU Chip Flash Content

Attack DSP MCU Chip Flash Content

Attack DSP MCU Chip Flash Memory and extract content from Microcontroller memory, through invasive MCU cracking to remove the silicon cap of microprocessor to disable the security fuse bit;

Attack DSP MCU Chip Flash Memory and extract content from Microcontroller memory, through invasive MCU cracking to remove the silicon cap of microprocessor to disable the security fuse bit

The acid is normally applied in small portions with a pipette into a pre-milled hole in a chip preheated to 50–70˚C (Figure 51). After 10–30 seconds the chip is sprayed with dry acetone from a washing bottle to remove the reaction products.

This process has to be repeated several times until the die is sufficiently exposed. To speed up the process, the chip can be placed in a sand bath and the acid can be preheated in a glass beaker.

Attack CPLD Chip Encrypted Code

Attack CPLD Chip Encrypted Code

Attack CPLD Chip program memory and data memory, cut off the security fuse bit by focus ion beam which is one of the most technique in microcontroller unlocking, and readout the firmware from CPLD memory;

Attack CPLD Chip program memory and data memory, cut off the security fuse bit by focus ion beam which is one of the most technique in microcontroller unlocking, and readout the firmware from CPLD memory

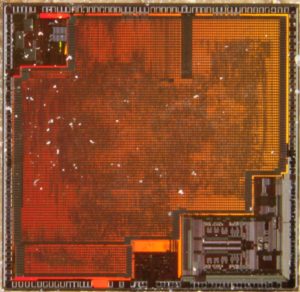

The process of manual decapsulation usually starts with milling a hole in the package so that the acid will affect only the desired area above the chip die (Figure 50). The tools necessary for this operation are available from any DIY shop for less than £10.

The commonly used etching agent for plastic packages is fuming nitric acid (>95 %), which is a solution of nitrogen dioxide NO2 in concentrated nitric acid HNO3. It is very strong nitrifying and oxidizing agent; it causes plastic to carbonise, and it also affects copper and silver in the chip carrier island and pins. Sometime a mixture of fuming nitric acid and concentrated sulphuric acid H2SO4 is used. This speeds up the reaction with some types of packages and also prevents the silver used in bonding pads and chip carrier from reacting.

Attack CPLD IC Microcontroller Source Code

Attack CPLD IC Microcontroller Source Code

Attack CPLD IC Microcontroller data memory by MCU cracking method and readout Source Code from CPLD memory after decapsulate the CPLD silicon package.

Attack CPLD IC Microcontroller data memory by MCU cracking method and readout Source Code from CPLD memory after decapsulate the CPLD silicon package

When attack CPLD IC microcontroller file, it is a common opinion that decapsulation is a complicated process which requires a lot of experience. In fact it is not and anyone capable of carrying out chemical or biological work in the context of a standard high-school program can do this.

All the necessary experience could be obtained by decapping a dozen different samples. Some precautions should be taken as the acids used in this process are very corrosive and dangerous; ideally, the work should be performed in a fume cupboard to prevent inhalation of the fumes from acids and solvents.

Eyes should be protected with safety goggles and appropriate acid-resistant gloves should be worn as the acid will cause severe burns if it accidentally comes into contact with the skin. Protective clothing should be worn as well.

Attack CPLD MCU Microcontroller Firmware File

Attack CPLD MCU Microcontroller Firmware File

Attack CPLD MCU Microcontroller and clone firmware file from MCU memory, and then rewrite the extracted source code to new CPLD MCU microcontroller for a perfect cloning;

Attack CPLD MCU Microcontroller and copy firmware file from MCU memory, and then rewrite the extracted source code to new CPLD MCU microcontroller for a perfect cloning

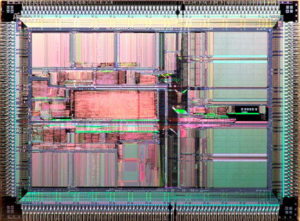

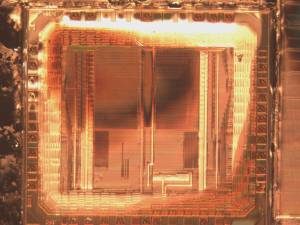

When attack cpld mcu microcontroller, To undertake further work under a FIB or a SEM the chip surface has to be coated with a thin gold layer making it conductive, otherwise it will very quickly accumulate charge and the picture become dark.

We used an Emitech K550 gold sputter coater to coat samples prior to the FIB work. Some modern FIB machines have a built-in video camera for optical navigation, eliminating the need for the special coating.

Read AVR Chip Embed Firmware

Read AVR Chip Embed Firmware

Read AVR Chip Embed Firmware out from program memory and software eeprom, the firmware format will be in heximal which can be used to manufacture AVR Microcontroller Cloning through MCU memory code extraction;

Read AVR Chip Embed Firmware out from program memory and software eeprom, the firmware format will be in heximal which can be used to manufacture AVR Microcontroller Cloning through MCU memory code extraction

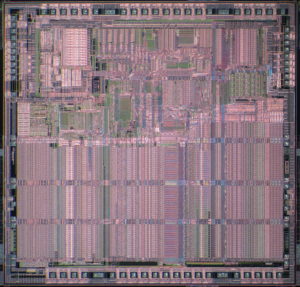

Invasive attacks start with partial or full removal of the chip package in order to expose the silicon die. There are several methods, depending upon the package type and the requirements for further analysis. For microcontrollers, partial decapsulation is normally used, so that the device can be placed in a standard programmer unit and tested. Some devices cannot be decapsulated and still maintain their electrical integrity.

In this case the chip die has to be bonded to a chip carrier using a bonding machine which connects to the bonding pads on the die with thin aluminium or gold wire (Figure 49). Such bonding machines are available from different manufacturers and can be bought second-hand for less than £5,000. The contacts to the die can be also established using microprobing needles on a probing station.

Read AVR IC MCU Chip Firmware

Read AVR IC MCU Chip Firmware

Read AVR IC MCU Chip Firmware from microcontroller flash memory, the status of AVR IC MCU has been reset from locked to opened one through Microcontroller unlocking by focus ion beam cut off security fuse bits;

Read AVR IC MCU Chip Firmware from microcontroller flash memory, the status of AVR IC MCU has been reset from locked to opened one through Microcontroller unlocking by focus ion beam cut off security fuse bits

Some operations such as depackaging and chemical etching can still be performed by almost anyone with a small investment and minimal knowledge. There are also some attacks, for example optical reading of an old Mask ROM memory, or reverse engineering of a chip built with 1 µm technology and two metal layers, where gaining the access to the chip surface is enough to succeed.

The necessary chemicals and tools are relatively cheap, and a suitable optical microscope could be bought second-hand for less than £1,000. Normally invasive attacks are used as an initial step to understand the chip functionality and then develop cheaper and faster non-invasive attacks.

Read AVR ATmel MCU Firmware

Read AVR ATmel MCU Firmware

Read AVR ATmel MCU Firmware from ATmel AVR microcontroller program memory and data memory, remove the package by focus ion beam which is one of the most commonly used methods in MCU crack for Microcontroller content copying;

Read AVR ATmel MCU Firmware from ATmel AVR microcontroller program memory and data memory, remove the package by focus ion beam which is one of the most commonly used methods in MCU crack for Microcontroller content copying

These read avr mcu attacks require direct access to the internal components of the device. If it is a security module or a USB dongle, then it has to be opened to get access to the internal memory chips. In the case of a smartcard or a microcontroller, the packaging should be removed followed by FIB or laser depassivation to get access to the internal wires buried deep under the passivation layer of the chip. Such attacks normally require a well equipped and knowledgeable attacker to succeed. Meanwhile, invasive attacks are becoming constantly more demanding and expensive, as feature sizes shrink and device complexity increases.

Read PLD Chip Binary Source Code

Read PLD Chip Binary Source Code

Read PLD Chip Binary Source Code is process of software decryption, through Microcontroller unlocking technique, engineer can reset the status of PLD Chip from locked to open, then readout firmware from Target PLD with universal programmer;

Read PLD Chip Binary Source Code is process of software decryption, through Microcontroller unlocking technique, engineer can reset the status of PLD Chip from locked to open, then readout firmware from Target PLD with universal programmer

Using encryption, where applicable, also helps make the data recovery from erased memory more difficult. Ideally, for secure applications, each semiconductor memory device should be evaluated against all possible outcomes of data remanence on its security protection.